Driving Sustainable Aluminum Manufacturing: Easy methods to Calculate the Materials Restoration Ratio with GraphFrames

Sustainable manufacturing has turn out to be an crucial in as we speak’s manufacturing market. In line with a 2022 survey by the Nationwide Affiliation of Producers, 79% of producers have particular sustainability objectives. One international chief in aluminum sheet and foil manufacturing has embraced this problem head-on, utilizing Databricks to research manufacturing line knowledge. This aluminium manufacturing firm goals to reinforce product high quality, optimize sources, and cut back environmental impression.

The Problem: Complexity in Manufacturing and Emissions Monitoring

Aluminum manufacturing is a fancy course of with many phases concerned in remodeling uncooked supplies into completed merchandise. To make sure sustainability all through this course of, the corporate has developed reporting methods that observe the environmental impression from begin to end. One of many key metrics on this effort is the restoration ratio—the share of aluminum efficiently recycled from scrap supplies into new merchandise. To precisely measure this, the corporate should first establish every step required in creating the tip product (e.g., “batch tracing”) after which calculate the fabric waste related to every stage.

The information, nonetheless, is very large. Manufacturing methods have recorded over 1 billion rows with as much as 40 ranges of linked manufacturing batches. Conventional DataFrame strategies weren’t well-suited for parsing these relationships from the info. The corporate thought of utilizing Pandas UDFs, however these UDFs confirmed efficiency limitations as the scale and complexity of the info elevated. Figuring out deeply-nested relationships in such a big dataset required modeling the relationships as a graph. An answer constructed with GraphFrames—a distributed graph-processing framework included in Databricks ML Runtime and optimized with Databricks’ Photon Engine—carried out the end-to-end batch tracing with good efficiency and scalability.

Working with GraphFrames

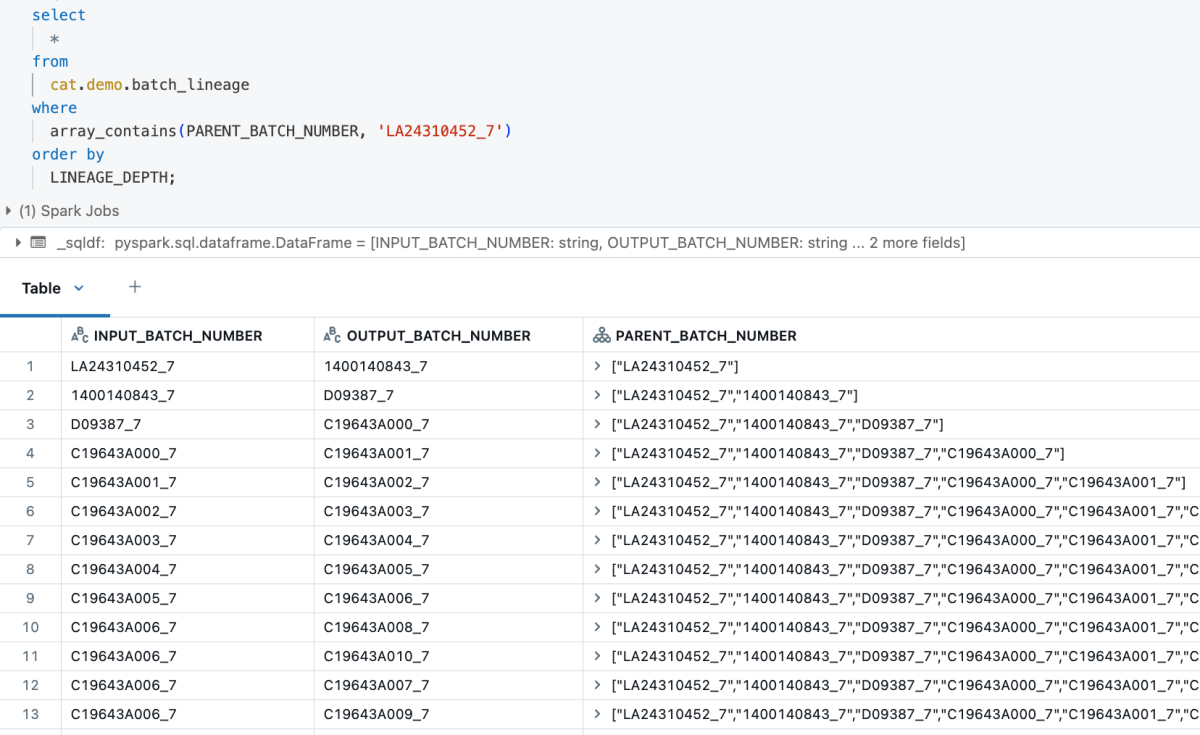

Manufacturing methods can refine a single uncooked materials into a whole lot of end-products with a whole lot of intermediate steps. Whereas every subprocess could emit details about its personal enter and output supplies, measuring key sustainability indicators just like the restoration charge requires evaluation of the end-to-end sequence. The objective is to attach an output batch with a supply batch by way of a collection of intermediate batch IDs. As soon as the complete hint is out there, we are able to decide the fabric misplaced in every step.

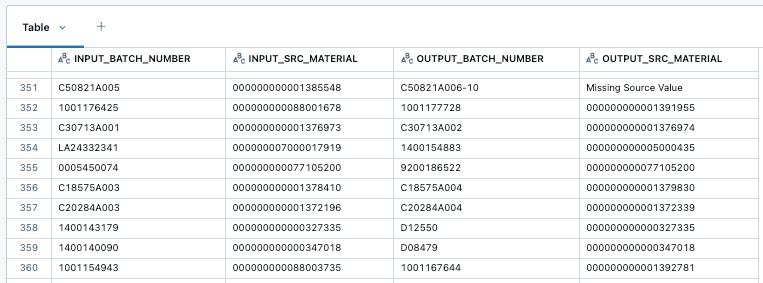

Tracing manufacturing batches saved as rows in a DataFrame—to compute the whole materials misplaced within the manufacturing of an end-product, for instance—might be troublesome. Whereas DataFrames are helpful for a lot of analytical queries over units of enterprise objects, they lack performance to mannequin and analyze complicated hierarchies of objects. GraphFrames are a helpful knowledge construction for coping with massive object hierarchies. They mannequin hierarchies as graphs with:

- Vertices representing the enterprise objects (e.g. Batch A from a producing course of)

- Edges representing the pairwise relationships between the objects (e.g. Batch A is the supply for Batch B)

The GraphFrames library has many built-in instruments for processing graph knowledge. One class of algorithms, Pregel, sends info alongside the graph edges to compute outcomes. For batch tracing, we used Pregel to ship details about earlier manufacturing steps (e.g. the output batch quantity) alongside the graph, producing a full listing of all upstream materials batches for every end-product.

Understanding Pregel

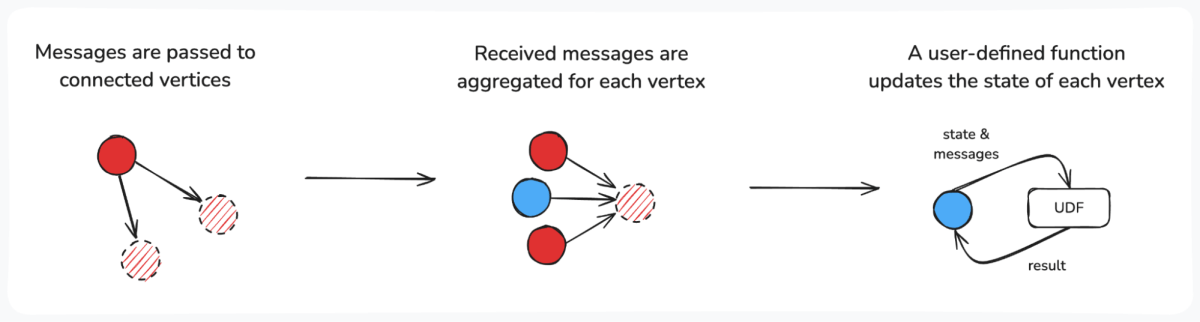

Pregel is a framework that enables customers to construct customized, parallelized message-passing algorithms suited to their distinctive enterprise issues. Every vertex is initialized with a default worth. Outcomes are computed over iterations referred to as supersteps. In every superstep, graph vertices can:

- Go a message to their neighbors

- Mixture messages obtained from their neighbors

- Course of the messages and replace their inner state

Person-defined features (UDFs) management how messages are handed and used to replace a vertex’s state. This flexibility permits customers to implement Pregel algorithms for a wide range of use-cases. To hint batches in our manufacturing course of, we despatched the enter batch quantity from one vertex to a different, updating every vertex’s depth and supply batch numbers when a message was obtained.

Defining Features for Batch Tracing

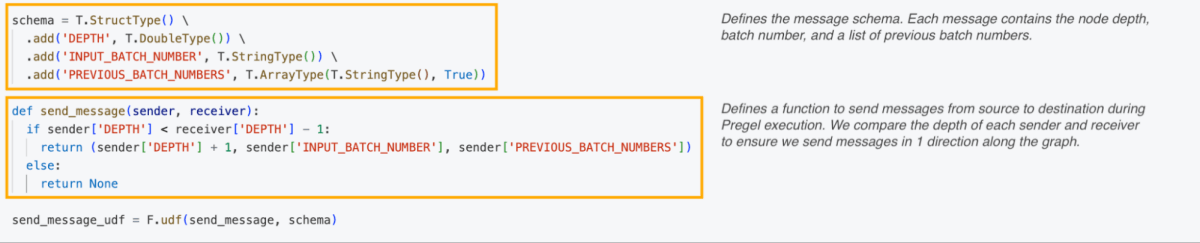

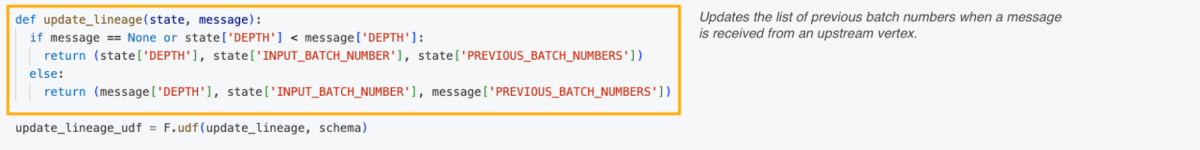

To implement batch tracing with Pregel, we needed to ship batch numbers alongside the graph. We began by defining a message construction—ours included the depth of the node, the batch quantity, and any earlier batch numbers (a.ok.a. the “hint”). With our message schema outlined, we created a UDF to make sure messages had been despatched from mother or father to little one batch based mostly on every vertex’s depth.

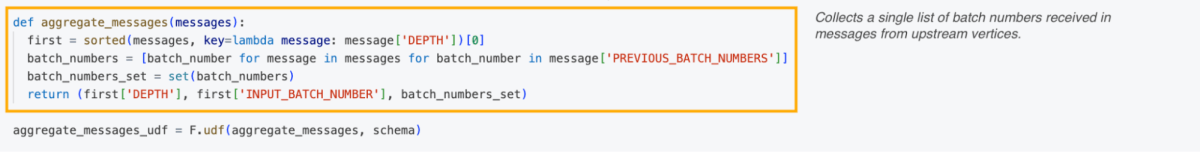

As a result of manufacturing methods can contain a number of inputs, we wanted a technique to deal with messages from a number of upstream vertices. We created a perform to gather a single listing of batch numbers obtained from every upstream manufacturing line.

Lastly, we created a perform to replace every vertex with the aggregated batch numbers.

Pre-Processing the Information

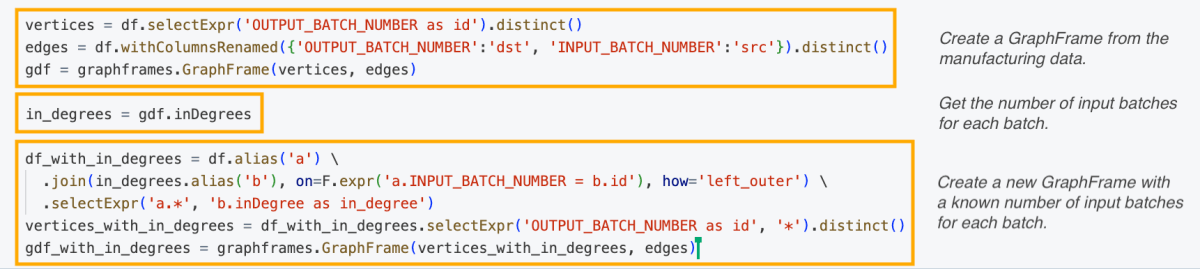

Our first step was to establish supply batches in our dataset. We created a GraphFrame from our batch knowledge and used the inDegrees property to find out the variety of enter batches for every output batch.

As soon as we had discovered the supply batches, we had been capable of assemble a Pregel algorithm to cross the batch quantity alongside every edge, from enter to output till the complete lineage was traced for each batch.

Working the Pregel Algorithm

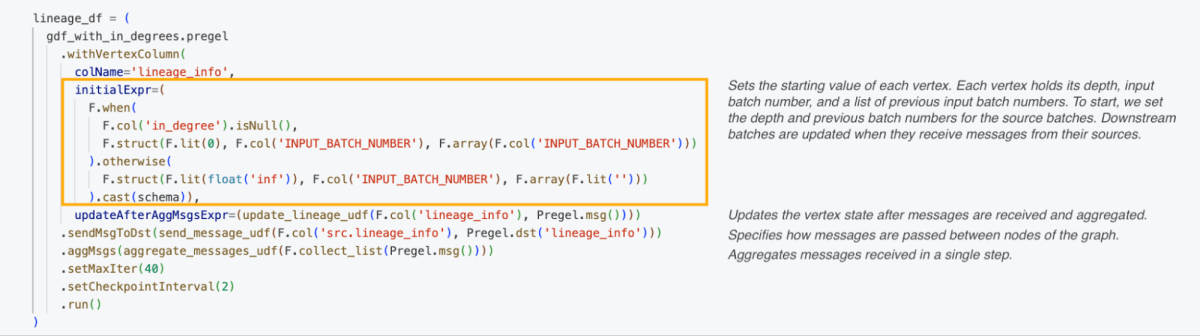

The picture under reveals the Pregel framework calls to execute the algorithm and hint the lineage.

GraphFrames sped-up hierarchical traversal by 24x (4 hours to about 10 minutes) for 1 million batches vs. Pandas UDFs working on the identical cluster. Whereas Pandas UDFs might solely be scaled by growing the employee measurement, checks confirmed that GraphFrames scaled horizontally when employees had been added to the cluster.

Conclusion

Utilizing GraphFrames on Databricks has supplied this producer larger visibility into its manufacturing course of. With reporting developed from batch tracing knowledge, operations managers can establish defects early, cut back waste, and ship extra constant product high quality. Monitoring waste and emissions extra precisely will assist the corporate reduce its environmental impression, guarantee compliance with more and more stringent rules, and higher align with its clients’ values.

Embracing data-driven options helped this producer discover extra environment friendly, sustainable methods of manufacturing items. GraphFrames gives handy, Spark-native graph performance that can be utilized by many producers to know their manufacturing processes at scale.

Concerned with driving sustainability in your online business? Take a look at our ESG Efficiency Evaluation options accelerator to get began!